Applied Aerodynamics Laboratory

About the lab

Western Michigan University's Applied Aerodynamics Laboratory, located at the Kalamazoo International Airport, is operated by the Department of Mechanical and Aerospace Engineering.

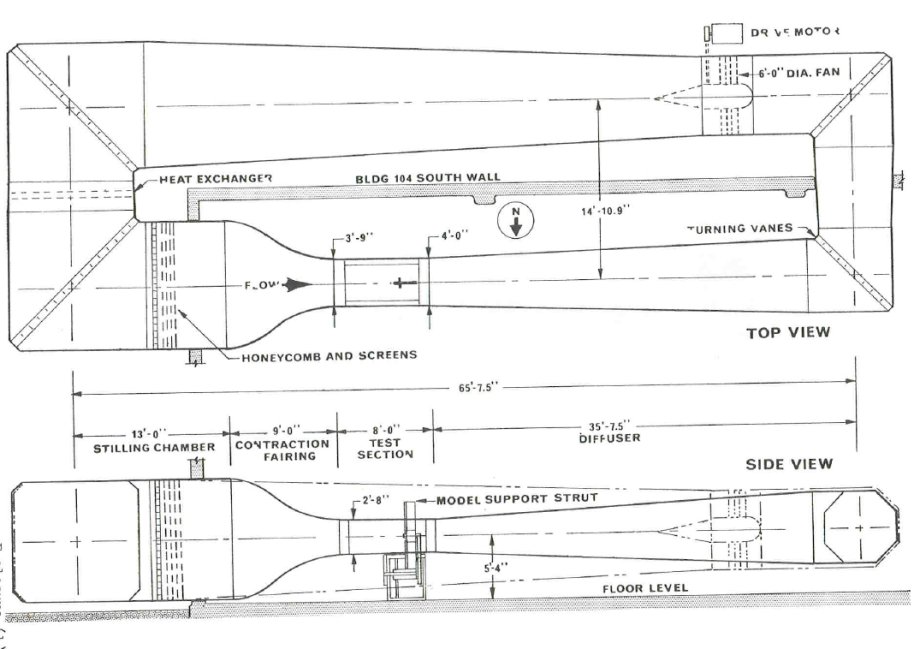

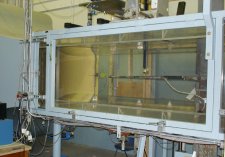

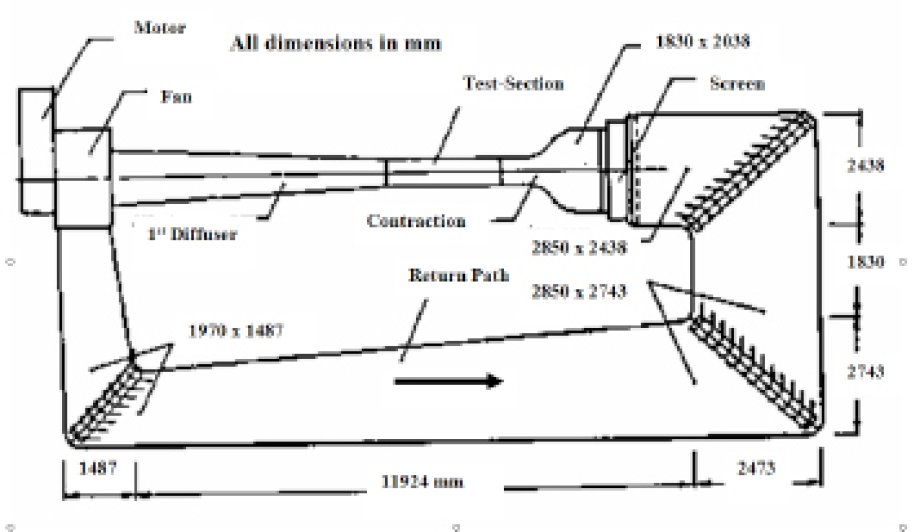

The laboratory houses the Advanced Design Wind Tunnel, the Small Wind Tunnel (SWT), and the GM Wind Tunnel (to be set up) and a small turbine engine test cell. The Applied Aerodynamics Laboratory conducts research in measurement techniques and experimental and applied aerodynamics.

The lab has close collaborations with other WMU labs, including the following:

- Fluid Mechanics Laboratory

- Computational Fluid Dynamics Laboratory

- other related departments at WMU

Contact

Dr. Tianshu Liu, Professor

Department of Mechanical and Aerospace Engineering,

G-217, Parkview Campus,

Western Michigan University, Kalamazoo, MI 49008, USA.

E-mail Tianshu Liu | (269) 276-3426

Fax: (269) 276-3421

Fax: (269) 276-3421

Selected research topics

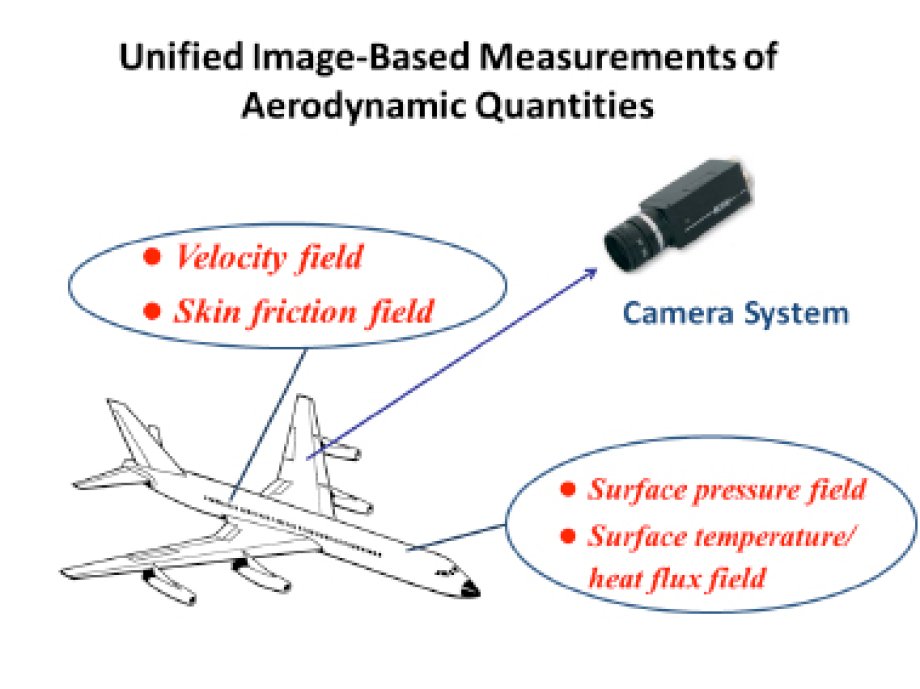

- Pressure and temperature sensitive paints in aerodynamics

- Fluid flow and optical flow: general framework for global flow diagnostics

- Geometric and kinematic aspects of image-based measurements

- Global luminescent oil-film skin friction meter

- Skin friction topology in complex separated flows

- Extraction of skin friction fields from surface flow visualizations as an inverse problem

- Analytical and numerical inverse methods for determining heat flux in TSP measurements in hypersonic wind tunnels

- Videogrammetry and vision for aerospace applications

- Airfoil/wing flow control using trailing edge devices

- Aeroship: hybrid fight platform for personal, near-space and planetary flight

- Scaling analysis of propeller-driven mars aircraft

- Flapping flight: scaling, geometry, kinematics, aerodynamics, design and testing\

- Wind oscillator for power generation

- Fluid mechanics of deposition of micron droplets on wall in turbulent flows